|

Documentation/Product Certification

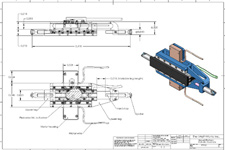

Our knowledge of certification requirements and proper documentation procedures are key to your success. We generate the proper documentation along the way, so certification will be a natural flow of the process. We follow engineering best practices which allow you to make changes dynamically with confidence the documentation is always up to date. We will provide design review records, part and assembly drawings, process flows, and can provide a complete manufacturing package that will allow you or the CM of your choosing to begin production immediately. This documented process will allow for product improvements, manufacturability, design reliability, quality and protect your intellectual property.

- Solid modeling (3-D CAD model generation for tooling)

- 2-D drawings

- Animated drawings

- 3-D rendered Marketing Material

- Assembly drawings

- Production documentation services

- Production and work flow process documentation

- Assembly and test documentation services

- DFM “Design for Manufacturability” review services

- Certification Support

- RoHS - Manage products to obtain certifications (European and Chinese)

- WEEE - Manage access for products requiring entrance to European Markets

- REACH - Manage products requiring compliance for REACH standards

- EMC - Manage compliance: FCC(US), CE(Europe), C-Tick(Australia/New Zealand), KCC(Korea), BSMI(Taiwan), VCCI(Japan)

- Safety - Manage products for UL, C/UL, TUV.

|